Steel Shots

Steel shots

Steel shot is spherical hardened steel abrasive media used for surface cleaning, peening, finishing, and strengthening parts. It’s widely used in abrasive blasting and shot peening to remove rust, scale, old coating, or to improve surface durability.

Key Benefits

- Uniform spherical shape

- Smooth surface finish

- High recyclability

- Consistent blasting performance

Most Ideal for cleaning and fatigue resistance applications.

Chemical Composition

| # | Chemical | Value |

|---|---|---|

| 1 | Carbon | 0.85% - 1.2% |

| 2 | Manganese | 0.60% - 1.2% |

| 3 | Silicon | 0.40% Minimum |

| 4 | Sulfur | 0.05% Maximum |

| 5 | Phosphorous | 0.05% Maximum |

| 6 | Density | 7.4 G/CC Minimum |

| 7 | Microstructure | Finely tempered Martensite |

| 8 | Hardness | 40-50 HRC special : 50-55 HRC 55-60 HRC |

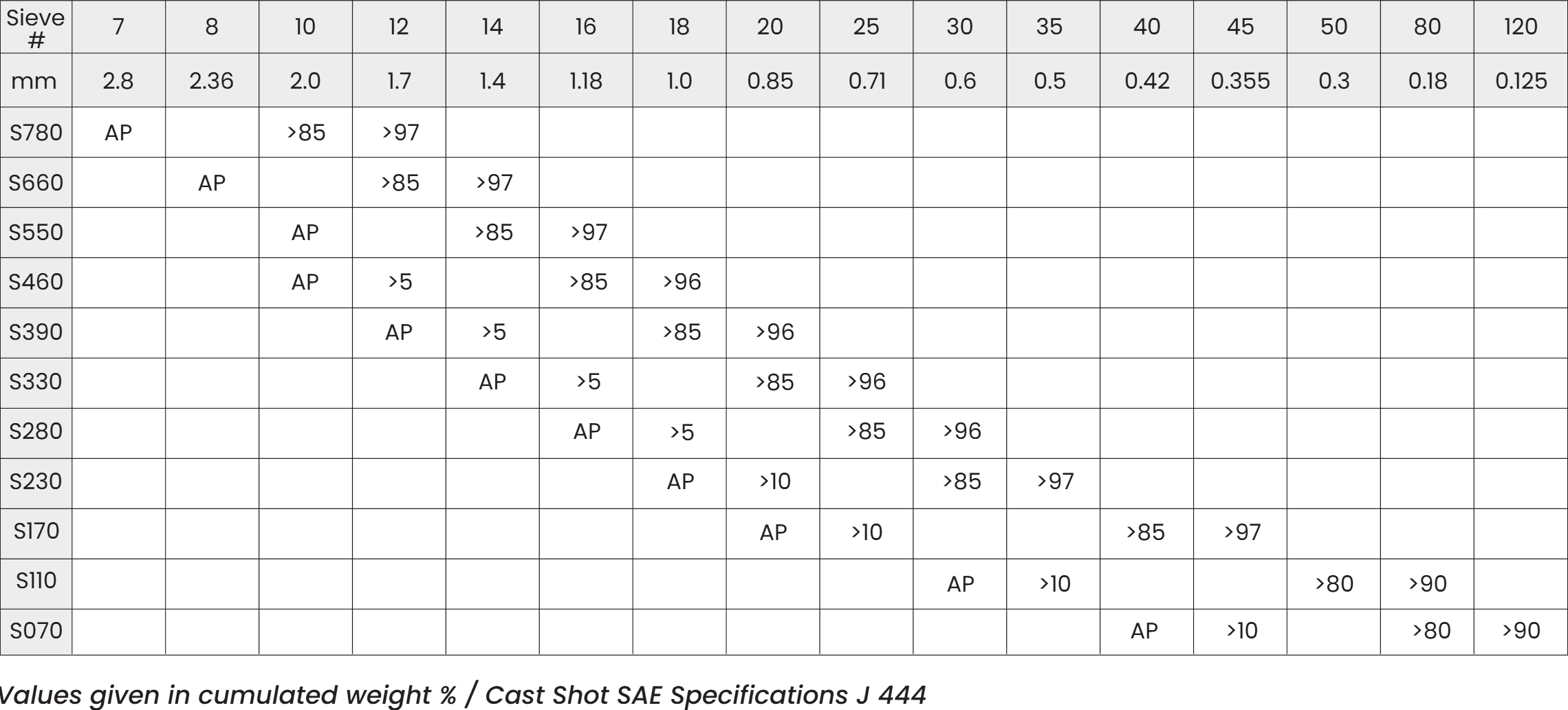

Steel Shot Grades, Sizes, Finishes & Applications

| # | Shot Grade | Finishing | Applications |

|---|---|---|---|

| 1 | S - 70 S - 110 S - 170 |

Fine, Smooth shot finsih. Excellent coverage. | Blasting of relatively small ferrous, non ferrous casting & machined parts. Removal of light scale from foreign, heat treated parts, mill scale, rust and other deposits. |

| 2 | S - 230 S - 280 S - 330 |

Medium, Light shot finish. Good coverage. | Blasting of grey iron, malleable iron, light steel castings, medium forgings, heat treated parts, heavy mill scale rust and other deposits. |

| 3 | S - 390 S - 460 S - 550 |

Average to heavy shot finish. Average coverage. | Blasting of steel, heavy malleable iron and grey iron castings. Removal of scale from large billets, slabs-rust. |

| 4 | S - 660 S - 780 |

Rough coverage. Adequate for most applications. | Heavy steel castings. Removal of tough, heavy scale. |